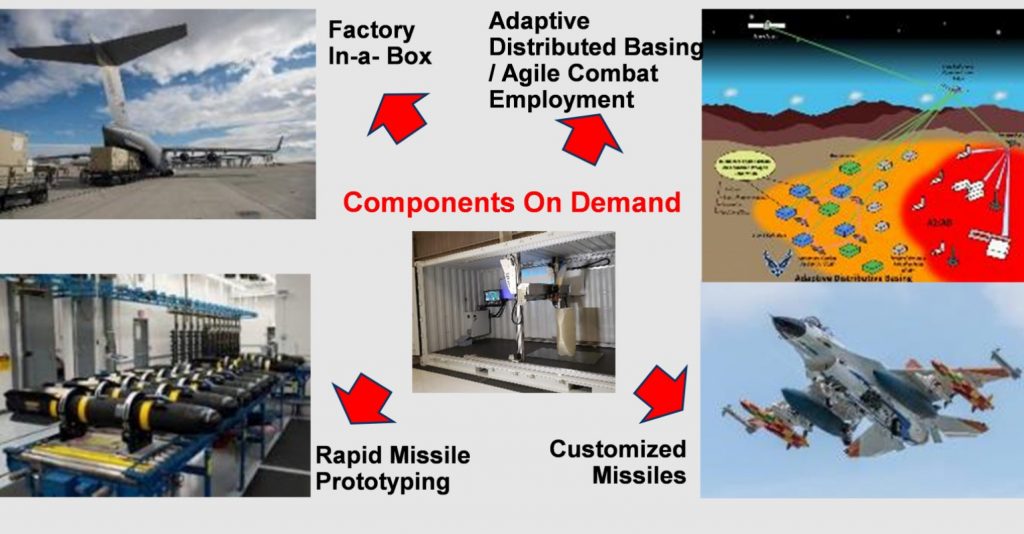

Solid rocket motors (SRMs) supplier X-Bow Systems Inc. (X-Bow) revealed that its Pathfinder I, a mobile energetics factory demonstration unit (aka Rocket Factory In-A-Box) will be delivered this month to the US Air Force Research Laboratory (AFRL) in Edwards, California.

Pathfinder I is part of X-Bow’s low-cost additive manufacturing approach to solid rocket motors, developed in conjunction with, and as part of, AFRL’s Eternal Quiver Program.

X-Bow’s Rocket Factory In-a-Box (RFIB) Pathfinder I is an inert demonstration unit of a mobile, containerized SRM “factory” that combines innovative design, automation, and additive manufacturing techniques.

Pathfinder I operates in a small footprint and increases flexibility in the manufacturing and fielding of rockets to specific missions.

AFRL describes the factory as mobile, small, and clandestine manufacturing centers for SRMs and weapons, designed to ensure continuity of necessary force application capabilities for warfighters. RFIB will prove beneficial to several key Major Commands including Air Combat Command, Air Mobility Command, Air Force Special Operations Command and Pacific Air Forces.

The X-Bow approach removes many design constraints and delays that are inherent to the current methods of producing SRMs, the company says.

“Advanced propulsion technology, cutting-edge manufacturing, and our talented and dedicated team of engineers are critical to developing next-generation rocket solutions,” said Jill Marsh, RFIB program manager at X-Bow System. “Over the next several years, X-Bow aims to work together with AFRL to identify projects and technologies to evolve the Pathfinder I capability for use in defense and other applications.”

“The pace of the world’s threats and evolution of capabilities means we cannot stand still. This demonstration unit will allow us to redefine what solid rocket motor production means in the 21st century,” said Dr Shawn Phillips, Chief Rocket Propulsion Division of AFRL Rocket Lab, located at Edwards AFB, CA.

According to AFRL, current rocket propulsion systems of air-launched missiles can take years to enter full rate production due to iterative design, build, and test methods practiced by industry. Furthermore, the US industrial base has consolidated into just a few manufacturing centers for bombs and missiles. AFRL believes the RFIB is key to avoiding potential strains placed on the US ability to provide sufficient and suitable weapons to the warfighter in future conflicts.